Helis Rulo

Helis Rulo

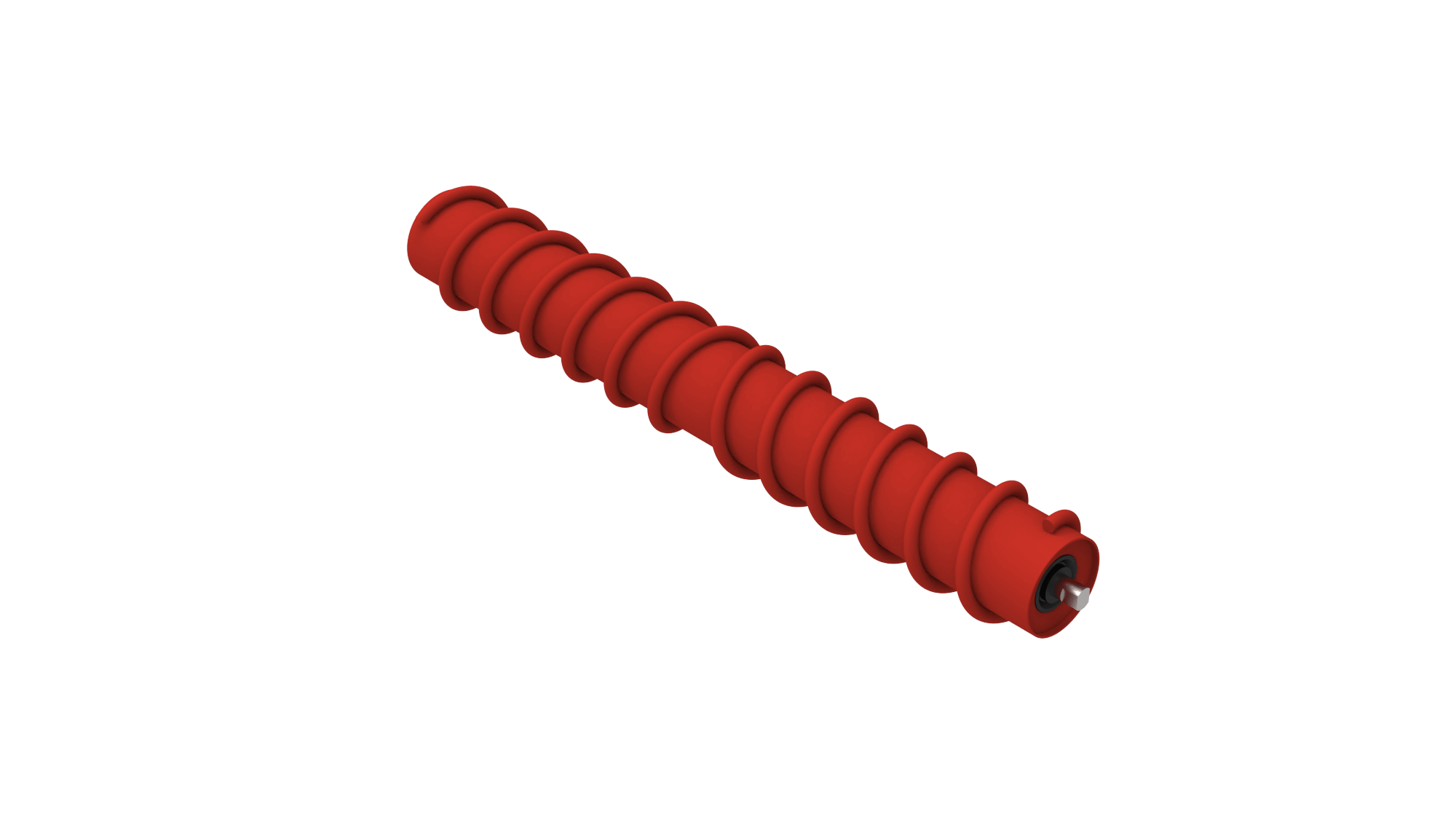

Helical rollers are rollers with a helical (screw-shaped) structure, generally used in conveyor systems and industrial transportation processes. These rollers have special designs that help to move materials while also directing them from one direction to another. Helical rollers are used especially in applications where materials need to be transported in an inclined or spiral plane.

Working Principle of Helical Roll

The helical roller has a spiral shape, just like a screw, and this shape allows materials to move in a fixed direction. The roller is usually used to transport materials in conveyor systems, and the movement of the roller ensures that materials are transported in a regular and controlled manner. The helical structure allows materials to move in different directions without slipping or scattering.

Rotational Motion: Helical rollers carry the material up or down as they move. The roller facilitates the transportation process by ensuring that the materials move smoothly and without slipping.

Inclined Conveying: Helical rollers are used in inclined conveying applications, allowing materials to be transported along an inclined line instead of a flat surface. This feature allows materials to take up less space and is easier to transport.

Spiral Structure: Since helical rolls have a spiral structure, they ensure that the materials move regularly and provide smooth transportation.

Properties of Helical Roll

Spiral Design: The main feature of helical rollers is that they have a screw or spiral shape. This design ensures that the materials move regularly and without slipping.

Durable Construction: Helical rollers are typically made of durable materials such as steel, stainless steel or plastic. These materials increase the roller's longevity and ability to carry heavy loads.

High Carrying Capacity: Helical rollers are generally suitable for carrying heavy and large materials and their carrying capacity is quite high.

Inclined Conveying: Helical rollers are ideal for conveying materials on inclined surfaces and prevent slipping during inclined conveying operations.

Low Friction: The helical roller reduces friction by remaining in contact with a smooth surface, making the conveying process more efficient.

Advantages of Helical Roll

Orderly Conveying: The helical roller ensures that the materials move smoothly and steadily. This makes the conveying process much safer and more efficient.

Inclined Transport Ability: Helical rollers enable space saving by ensuring that materials are transported smoothly even on inclined surfaces.

High Carrying Capacity: Used effectively in carrying heavy and large loads.

Long Life: Since it is made of durable materials, it works without any problems for a long time.

Fast and Efficient Transport: It ensures fast and efficient transport of materials, which increases the overall efficiency of the system.

Areas of Use of the Helical Roles

Food Industry: Helical rollers placed especially on inclined surfaces during the transportation of food products ensure that the products are transported in an orderly manner.

Mining: Helical rollers are used in the mining industry to move heavy materials, making transportation more efficient.

Automotive Industry: In production lines where automotive parts are transported, helical rollers ensure that the materials are transported in an orderly manner.

Manufacturing and Assembly Facilities: Used in assembly lines to transport small parts and components.

Transportation and Storage: It can be used to transport materials in an orderly manner in transportation systems and storage areas.

Helical roller is a special type of roller used in inclined surfaces or spiral conveying processes in conveyor systems. Thanks to its spiral structure, it makes the conveying process more efficient by ensuring that the materials are carried in a regular manner without slipping. It stands out as an important component in industrial conveying systems with its durable structure, high carrying capacity and inclined carrying ability.