Garland Roller

Garland Roller

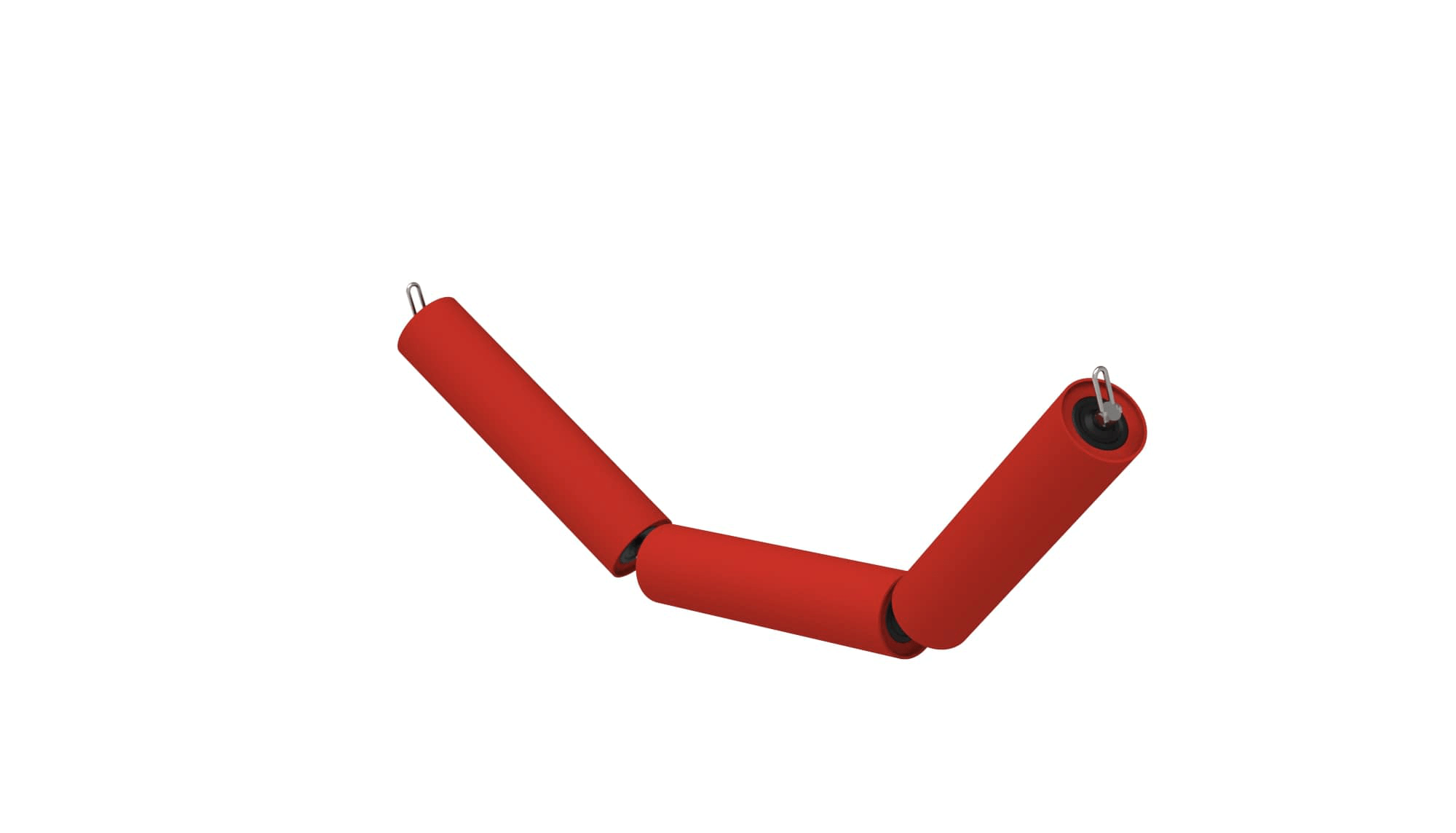

Garland rollers refer to a series of rollers used to ensure the smooth operation of conveyor systems. These rollers are especially used in inclined or flat conveyors to support the conveyor belts and prevent the materials from slipping. The main feature of the garland roller is that the rollers are arranged in a specific pattern, enhancing the integrity and efficiency of the system.

Garland Roller Working Principle

Garland rollers typically work by operating multiple rollers together, ensuring more stable operation of conveyor belts. These rollers are arranged in a "triple" or "quadruple" configuration, helping the conveyor belt move more smoothly and in a controlled manner. The Garland roller works parallel to the surface of the conveyor belt, preventing materials from slipping, tipping over, or falling off the belt.

Garland rollers typically work by operating multiple rollers together, ensuring more stable operation of conveyor belts. These rollers are arranged in a "triple" or "quadruple" configuration, helping the conveyor belt move more smoothly and in a controlled manner. The Garland roller works parallel to the surface of the conveyor belt, preventing materials from slipping, tipping over, or falling off the belt.

- Horizontal and Vertical Support : When used on inclined surfaces, Garland rollers support the conveyor belt both horizontally and vertically. This ensures that materials are transported smoothly even on inclined surfaces.

- Stable Transport : These rollers ensure smooth operation of conveyor belts, preventing materials from falling or slipping, while also increasing the overall durability of the belt system.

- Roller Arrangement : Garland rollers are usually arranged in sets of 3 or 4, which increases load-carrying capacity, especially on long and inclined conveyors.

Features

- Smooth Transport : Garland rollers stabilize the transport process, preventing materials from slipping or falling off during transport.

- Durable Construction : Garland rollers are usually made of durable materials like steel, stainless steel, or plastic, making them long-lasting and suitable for tough working conditions.

- Suitable for Inclined Surfaces : Garland rollers balance the slope of inclined conveyor systems, ensuring materials are transported more safely.

- Easy Maintenance : Garland rollers are typically easy to maintain and long-lasting. Roller systems can be quickly and efficiently serviced.

Advantages

- Material Protection : Garland rollers prevent materials from slipping off or sliding, ensuring safe transport.

- Transport Efficiency : These rollers allow conveyor belts to operate more efficiently and without issues, speeding up the transport process and improving energy efficiency.

- High Load Capacity : Garland roller systems offer high carrying capacity on long and inclined conveyors, allowing large quantities of materials to be transported safely.

- Low Friction : Garland rollers reduce friction during transport, making it possible to transport materials with less energy.

Applications

- Mining : In the mining industry, Garland rollers are used to make conveyor belts more resistant to tough working conditions and to safely transport materials.

- Automotive Industry : Garland rollers ensure efficient operation and prevent material slippage on conveyor belts used in automotive part transportation and assembly lines.

- Logistics and Storage : Garland rollers are used in storage and distribution centers, particularly on long and inclined belts, to ensure safe material transport.

- Food Industry : In the food industry, especially on inclined conveyor lines, Garland rollers are used to ensure safe and smooth transport of materials.

- Textile Industry : Garland rollers are used in textile machines to ensure the smooth transport of fabrics.

Garland rollers are an important component of conveyor systems, ensuring safe, smooth, and efficient transport of materials. Their durable construction, ability to work effectively on inclined surfaces, and low friction properties make Garland rollers highly valuable in various industries. These rollers make transportation safer and more efficient, especially over long distances and in challenging conditions.